The Lumbering Process

Next | Previous | Return to Start

|

Lumbering has four phases: logging, driving, manufacturing, and transport. The details varied depending on whether a homesteader was carving a farm out of a forest, an independent logger was felling and selling logs to a mill, or a commercial mill handled the entire process from logging through sales. Early on, logging was generally limited to the winter months, mid-November through mid-March weather permitting, when horses or oxen could drag felled and trimmed logs and sleighs of logs on snow-covered ground to collection points at the edge of a nearby river, lake, or later a railway stop. With the invention of big wheels, logs could be more easily moved throughout the year. Driving involved getting logs from a collection point to a sawmill. Early on this generally meant floating logs down a river after the spring thaw, which was a dangerous ride for the men called "river hogs." When a stream was not available as was the case for Arcadia, railroads were used to get logs to mills throughout the year and much more safely. Manufacturing wood products involved cutting logs into lumber and other wood products. Early on, this might have been as low tech as moving the log over a hole deep enough for a man to stand and then using a two-man saw to cut up and down the length of the log. Where a dependable source of moving water was available, water powered mills made the process more efficient, and just a couple men could produce many more board feet per day. Later steam-powered systems linked to belts could drive a series of saw blades and increase output dramatically. Transporting wood products involved finding a buyer, taking the products to market, and selling wood products. Small local mills would sell to local people who carried lumber home with them. With improved manufacturing techniques, mills could produce much more lumber than was needed locally, and the excess could be taken to market by sailing ship, steam ship, rail, and eventually trucks. |

Process Details |

Logging Near Arcadia“After selection, a chopper used an axe to fell the trees, laying them parallel to a newly cut road. Felling was the most demanding job in terms of skill and precision and made the chopper the “aristocrat” of the camp, sawyers then took over, squaring the butt end and removing the branches with cross-saws. At this point, the tree also might be “bucked” or cut into logs, although some operators waited to buck at the river’s bank.” -- Barbara E. Benson. 1989. Logs and Lumber: The Development of the Lumber Industry in Michigan's Lower Peninsula, 1837-1870. Page 90.

|

|

|

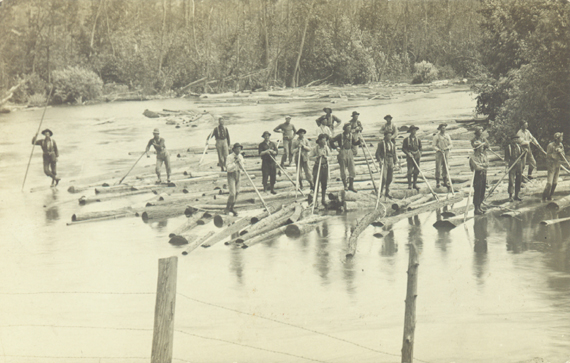

Driving Logs to the MillEarly lumbering was limited to trees along the edge of navigable streams and rivers. In the spring when the snow melted and spring rains swelled waterways, logs that had been piled up nearby were pushed in and directed downstream by men riding the logs. Even with spiked shoes and long pike poles, this was a dangerous job. Logs would roll. Rivers would vary in speed and direction. Obstacles could appear out of nowhere. Logs would get stranded or pile up in log jams. Managing these logs downstream was a job for the fearless athletes of spring, the "river hogs."

When sawmills shared the same waterway or storage area, logs were branded with a log mark used to identify the owner. To do that, a hammer with a log mark was used to pound an impression into the end of each log. For example, the Starke Land & Lumber Company used a log mark that consisted of a star containing a letter K for "star K" or a picture of a key for "star key." At the end of a trip downstream, river hogs would use each log's mark to sort logs into each owner's storage area built from logs chained together.

|

Around 1870 Sylas C. Overpack of Manistee began building and selling big wheels like the ones shown here. Initially the wheels were the size of standard wagon wheels, but larger wheels could lift more and bigger logs, so he soon began using wheels ten or twelve feet in diameter. Big wheels made summer logging easier, especially when combined with railroads that could carry logs the rest of the way to the mill. |

|

|

|

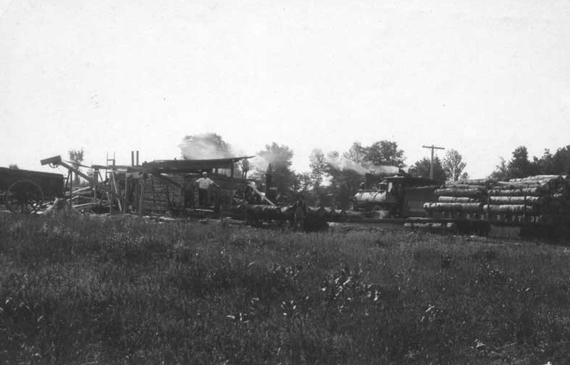

Arcadia's Lumbering RailwayWith the advent of narrow gauge railroads, logging became a year round business. No longer did driving involve floating logs down a river in the spring. Instead, logs were piled up next to conveniently located railroad tracks where they could be loaded onto cars and hauled by steam engine to the mill. In 1881, Henry Starke began construction of a narrow gauge railway used to carry logs to the mill. In 1893, Henry Starke began work on a standard gauge railway that also provided passenger and freight service that could connect to still more standard gauge rails. Arcadia could deliver logs and lumber east to the rest of the world.

|

|

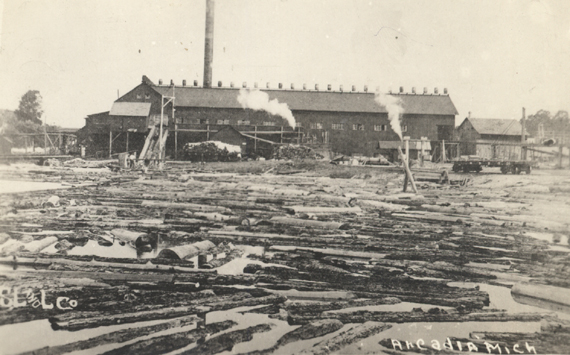

Manufacturing Wood Products

|

|

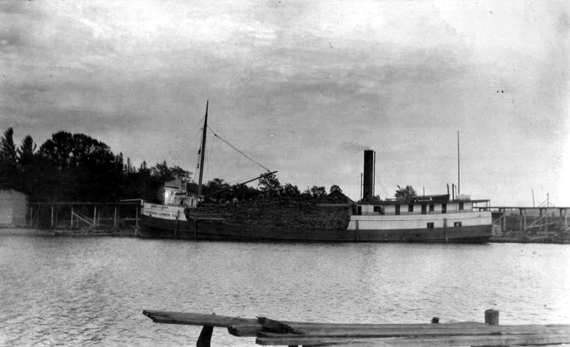

Transporting Arcadia's Wood Products

|

|

Using a Sleigh to Move Logs

Using a Sleigh to Move Logs

B

B

The Head of a Log Marking Hammer

The Head of a Log Marking Hammer A Marked Log End

A Marked Log End

The Trestle East of Arcadia

The Trestle East of Arcadia Crane and Big Wheels

Crane and Big Wheels A Sawmill Out in the Country

A Sawmill Out in the Country Logs Delivered to the Starke Sawmill

Logs Delivered to the Starke Sawmill  Sawmill Workers

Sawmill Workers The Arcadia Approaching the Sawmill

The Arcadia Approaching the Sawmill Loading Lumber onto the Neff

Loading Lumber onto the Neff Another View of the Neff Loaded with Lumber

Another View of the Neff Loaded with Lumber Logs on Railway Cars

Logs on Railway Cars